While combining the advantages of fluoride and silicone rubbers, fluorosilicons are a unique material demanded for the manufacture of products operating in the environment of petroleum products (gasoline, diesel fuel, transformer oils and other mineral types of oils and greases).

Features of fluorosilicones

Resistance to any petroleum products, as well as a wide range of aggressive chemicals, including acids, alkalis and solvents.

- Operating temperature range is from -600C to + 2000C.

- High resistance to ozone aging and gas.

- Resistant to sunlight and UV radiation.

- Low level of compression set. Even at extreme temperatures, products do not become excessively soft or fragile.

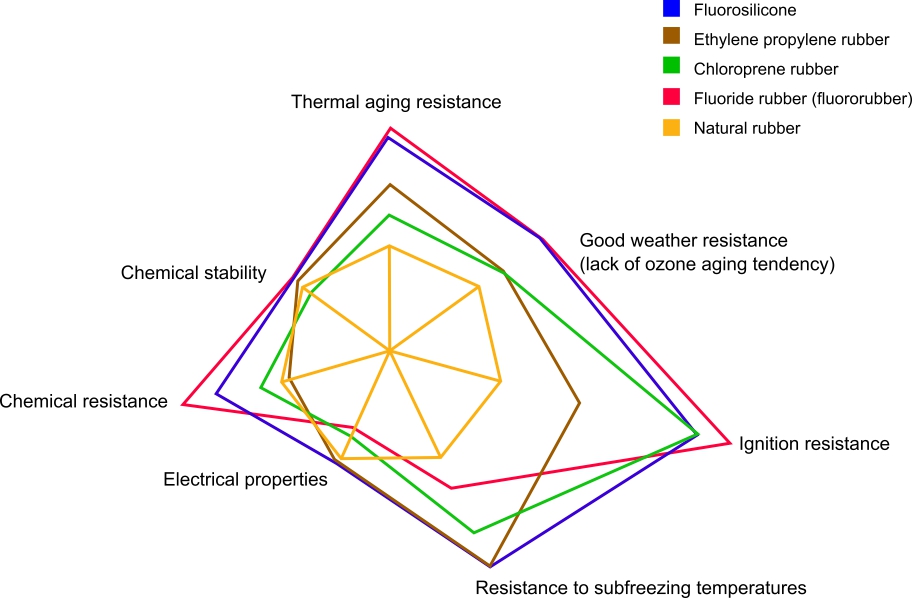

Comparison of characteristics of various types of rubber

Physical and mechanical properties of fluorosilicone rubber

| Type | Shore hardness | Nominal tensile strength (МPа) | Elongation at break (%) | Tear strength (кN/m) | Compression set, % (22 h х 177оС х 25%) | Linear shrinkage (%) |

| FlexiSil-96XX | 58-65 | 8,0 | 350 | Not more than 14 | Not more than 20 | 3,5-4,0 |

| FlexiSil-97XX | 68-75 | 7,5 | 300 | Not more than 14 | Not more than 20 | 3,5-4,0 |

Resistance of rubber in various environments

| Environment | Test conditions (time/temperature) | Hardness (Shore) | Change of indicators | ||

| Tensile Strength (%) | Elongation at break (%) | Volume (%) | |||

| Diesel fuel | 1 week / 60оС | -7 | -23 | -18 | 5 |

| 1 week / 60оС | -6 | -31 | -21 | 5 | |

| 3 months / 60оС | -3 | -32 | -32 | 5 | |

| IRM 902 Oil | 72 hours / 150оС | 0 | -7 | -8 | 1 |

| IRM 903 Oil | 72 hours / 150оС | -4 | -11 | -15 | 2 |

| ASTM Oil #1 | 72 hours / 150оС | -5 | 0 | -5 | 0 |

| ASTM Oil #3 | 7 days /150оС | 1 | -3 | -6 | 0 |

| Unleaded gasoline | 24 hours / 100оС | -11 | -16 | -29 | 20 |

| Ethylene glycol 50% | 24 hours / 100оС | 0 | -5 | 5 | 0 |

| Transformer Oil | 72 hours / 250оС | – | – | – | -1,5 |