Fluorosilicone Rubber (FVMQ, fluorosiloxane elastomer) when used as gaskets and seals in power oil transformers possess the following advantages:

- Service life up to 30 years.

- Resistance to all types of transformer oils. Minimal swelling and permanent compression deformation guarantee no leaks during the entire period of service.

- Rubber does not contain sulphur. Sulphur is not washed out with oil, followed by precipitation, which dramatically reduces the performance of the transformer.

- The upper limit of the operating temperature is 2500C.

- Electrical resistance is hundreds of times higher than in traditional insulating materials.

- It does not age outdoors.

We are ready to offer our customers both standard seals and their manufacture according to the drawings.

Standard Transformer Seal Types

Sealing cords of round and rectangular section

- 60 and 70 Shore hardness.

- Section diameter (for round cords) is from 2 to 50 mm. Side size (for rectangular cords) is from 2 to 40 mm.

- Supplied in reels of infinite length.

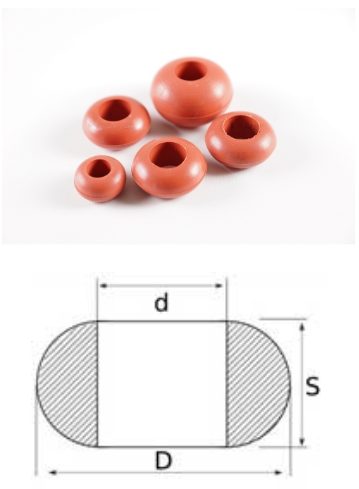

Semi-circular gaskets (typical sizes)

| S | D | d |

| 11 | 24 | 12 |

| 11 | 22 | 12 |

| 12 | 20 | 8 |

| 13 | 23 | 10 |

| 13 | 32 | 20 |

| 18 | 34 | 16 |

| 18 | 34 | 18 |

| 18 | 38 | 20 |

| 18 | 45 | 27 |

| 18 | 51 | 33 |

| 18 | 60 | 42 |

| 18 | 66 | 48 |

| 24 | 57 | 33 |

| 24 | 66 | 42 |

| 24 | 72 | 48 |

| 28 | 100 | 72 |

Rectangular gaskets (typical sizes)

| h | d | D |

| 4 | 10 | 18 |

| 4 | 27 | 49 |

| 4 | 45 | 70 |

| 6 | 28 | 45 |

| 6 | 36 | 56 |

| 6 | 52 | 80 |

| 6 | 65 | 96 |

| 6 | 78 | 104 |

| 6 | 90 | 120 |

| 6 | 110 | 150 |

| 8 | 42 | 62 |

| 8 | 45 | 85 |

| 8 | 255 | 279 |

| 8 | 315 | 339 |

| 10 | 58 | 70 |

| 12 | 45 | 65 |

Physical and Mechanical Properties of Fluorosilicone Rubber

| Density (g/cm2) | Hardness (Shore) |

Nominal tensile strength (МPа) |

Elongation at break (%) |

Tear strength (кN/m) |

Compression set % (22 hours х 170оС х 25%) |

Linear contraction (%) |

| 1,39-1,45 | 58-65 | 8,0 | 350 | Not less than 14 | Not more than 20 | 3,5-4,0 |

| 1,39-1,45 | 58-65 | 7,5 | 300 | Not less than 14 | Not more than 20 | 3,5-4,0 |

Rubber Resistance in Various Environments

| Environment | Test conditions (time/temperature) |

Hardness (Shore) |

Change of indicators | ||

| Tensile Strength (%) | Elongation at break (%) | Volume (%) | |||

| Diesel fuel | 1 week / 60оС | -7 | -23 | -18 | 5 |

| 2 week / 60оС | -6 | -31 | -21 | 5 | |

| 3 months / 60оС | -3 | -32 | -32 | 5 | |

| IRM 902 Oil | 72 hours / 150оС | 0 | -7 | -8 | 1 |

| IRM 903 Oil | 72 hours / 150оС | -4 | -11 | -15 | 2 |

| ASTM Oil #1 | 72 hours / 150оС | -5 | 0 | -5 | 0 |

| ASTM Oil #3 | 7 days / 150оС | 1 | -3 | -6 | 0 |

| Unleaded gasoline | 24 hours / 100оС | -11 | -16 | -29 | 20 |

| Ethylene glycol 50% | 24 hours / 100оС | 0 | -5 | 5 | 0 |

| СЖР-1 | 72 hours / 250оС | – | – | – | -1,5 |

| СЖР-3 | 72 hours / 250оС | – | – | – | 1,9 |