Lining is a special finish on the inner surface of the ore grinding mill protecting it from mechanical and physical damage. The need for lining is due to the fact that when grinding ore, the walls of the mill drum are subjected to continuous exposure to different fractions of ore. The lining not only protects the mill from premature failure, but also directly participates in the grinding process, providing effective mixing.

Traditionally, mining equipment uses metal lining. However, the transition to rubber provides a number of significant advantages:

- The cost of rubber lining is lower by 20-30 % with the same service life;

- The weight is less, which facilitates transport, installation and dismantling;

- Reducing the total weight also reduces the energy consumption of the operating mill by 10%;

- No corrosion;

- Rubber lining significantly reduces the noise level, which is very important for the labour protection of employees of mining and processing enterprises.

BGF Rubber conducts a full range of works on re-equipment of ore grinding mills and their transfer to rubber lining. Based on the model of mining and processing equipment, the design, putting into production, joint tests of lining with the customer are carried out. Warranty is provided.

Generic Lining Products

Overall wear-resistant plates

Used for cladding large areas of the mill. They can also be used to protect the surface of ore passes, trolleys and dump trucks. Allow to effectively cover and protect the work surface. They are made from special grades of rubber with maximum resistance to abrasion and the action of aggressive solutions and suspensions. The design of the plate provides for the presence of technical recesses and holes for fasteners.

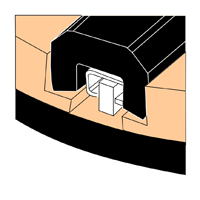

Lifters

These are protruding parts of lining of the ore grinding mill. In addition to protecting the surface, they are also directly involved in the grinding process, lifting the ore and ensuring its movement in the drum. The most typical installation scheme is a plate-lifter scheme.

These are protruding parts of lining of the ore grinding mill. In addition to protecting the surface, they are also directly involved in the grinding process, lifting the ore and ensuring its movement in the drum. The most typical installation scheme is a plate-lifter scheme.

As well as overall plates, the wear-resistant plates are made from special grades of rubber, which ensures effective and long-term operation.