Silicone extrusion is widely used for sealing ovens, boilers, spray booths, and other similar industrial appliances. Usually, it seals doors or hatchways and provides necessary thermal isolation for a long period of time. Less often demanded sealings for motionless parts.

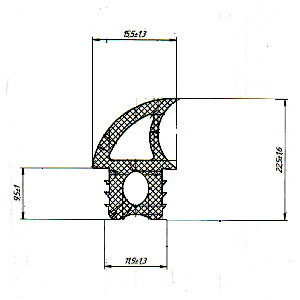

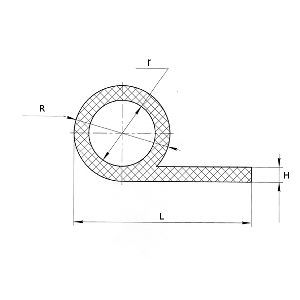

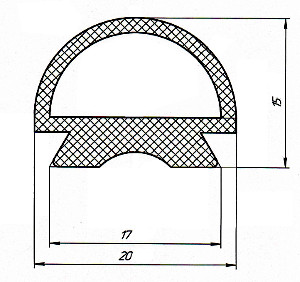

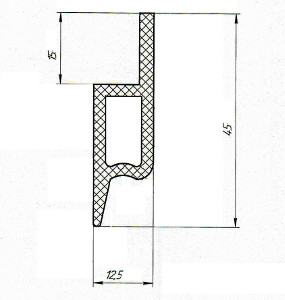

Ectrusion`s geometry depends on working conditions. The bottom part of extrusion developed with respect to mounting sit and provides reliable fixation. The working part has to guarantee full closing and isolation.

During its work period, extrusion has not to lose its shape and become flat. This is the main reason for using silicone and not any other materials. Silicone provides not just the highest temperature resistance impossible for any other rubber, but also a perfect compression set (ability to keep its shape under compression in other words).

Main properties:

Group I. Temperature from -60 to +250 С.

Group II. Temperature from -60 tо +300 С.

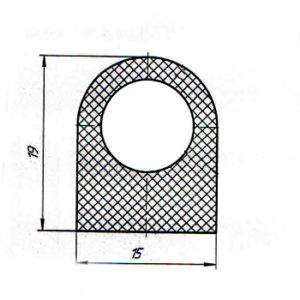

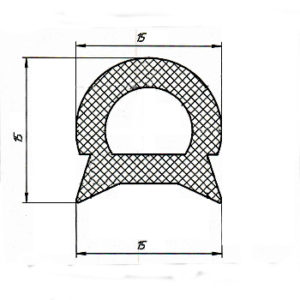

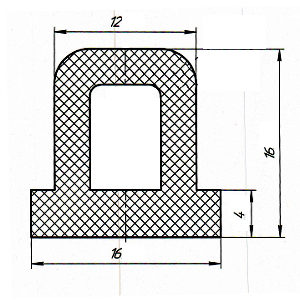

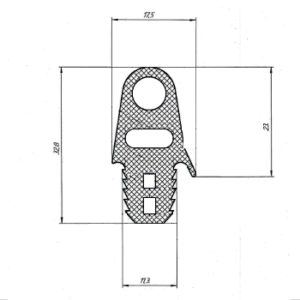

Silicone extrusion types:

|

|

|

|

|

|

|

|